Loading scale VW-500

The VW-500 loading scale has been developed for modern silo logistics. This system is indispensable due to the very high levels of accuracy it achieves. For standard products such as granulate, sugar, etc., these are +/- 20 kg for a loading quantity of 25,000 kg.

This prevents the vehicle from being overloaded. It is also possible to load individual compartments of the vehicle with precision.

The system is approved for calibration in accordance with MID 2014/32/EU and eliminates the need for a second weighing of the vehicle. Order management can be automated by connecting to customer databases or software systems such as SAP. All weighing data is stored in an alibi memory for at least 3 months. Depending on customer requirements, specifications or performance, the system can be integrated into existing silo systems.

Einsatzgebiete

Kunststoffe

Düngemittel

Nahrungsmittel

Getreide / Tiernahrung

Recycling /

feste Brennstoffe

Mineralische Produkte

Chemische Produkte

Mehle

At a glance.

Modular & adaptable

Integrated loading telescopes for self-loading

High accuracy

up to 150 tonnes per hour

Flexible use

Freely movable, can be moved by hand or with a motorised moving aid, and mobile.

Highest precision

Verifiable weighing technology in accordance with EU directive

Identification

Identification of the lorry and silos using RFID, for example, to prevent mix-ups during loading.

Technische Daten

-

Resolution

+/- 20 kg with a loading capacity of 25,000 kg

-

Performance

Up to 150 tonnes per hour

-

Weighing technology

Calibratable in accordance with EU Directive 2014/32/EU

-

Dosing systems

Option 1:

Outlet flange system:

Here, a pipe with a seal is lowered onto the outlet flange provided by the customer.Option 2:

Telescopic pipe system for non-dusting products:

This requires a ceiling opening of at least 500 mm. The telescopic pipe is lowered by the lorry driver to fill the lorry.Option 3:

Loading telescopes for powdery/dusty products. The motorised loading telescopes can be integrated into the loading weighbridge as well as into the track level.

Control

The scale has a self-sufficient control system with integrated, calibratable weighing electronics and a Siemens S7 PLC. The scale can be operated entirely via the touch panel. The connection to the silo control system is made via plug contacts with the signals “Silo open” and the feedback signals, as well as via the corresponding approvals.

Silo connection

The silo connection can also be made in a variety of ways. Here, there is the option of a press-fit device that presses firmly against the silo outlet. Alternatively, there is also a pipe system that slides around the silo outlet pipe without a fixed connection. A positioning accuracy of at least +/-50 mm is guaranteed.

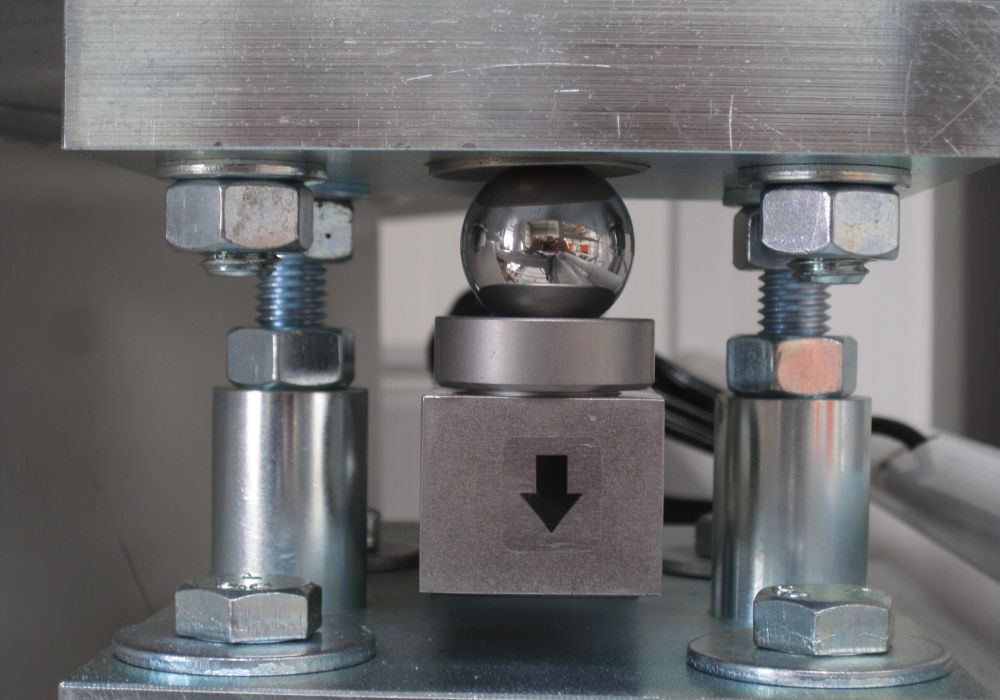

Weighing system

In such systems, the weighing vessel is usually designed with a nominal filling capacity of 500 kg. The vessel outlet must be sufficiently large to allow rapid emptying. All weights are recorded in a manner that allows calibration. The weighing container is connected to three high-precision ball supports.