Pneumatic packer Ilersac VBF

The Ilersac VBF pneumatic packer is a machine specially designed for filling powdery or fine-grained products in valve bags. Based on the principle of fluidizing the product during the filling process, this uncomplicated and robust machine finds a wide range of applications in a wide range of sectors such as the chemical industry, mining, construction, food and milling industries, etc.

Products such as PVC powders, resins and fatty products that are sensitive to mechanical contact (unavoidable in filling equipment with worm gears, conveyor belts or turbines) are filled correctly with the PFG because such drive mechanisms are not present.

The Ilersac VBF pneumatic packer is characterised by gentle filling. Optimal cleaning options thanks to a large, easily accessible bottom opening in the product container. Very low maintenance costs, wear-free weighing technology through the use of fully electronic weighing components. Legal-for-trade approval, according to national and European approval authorities.

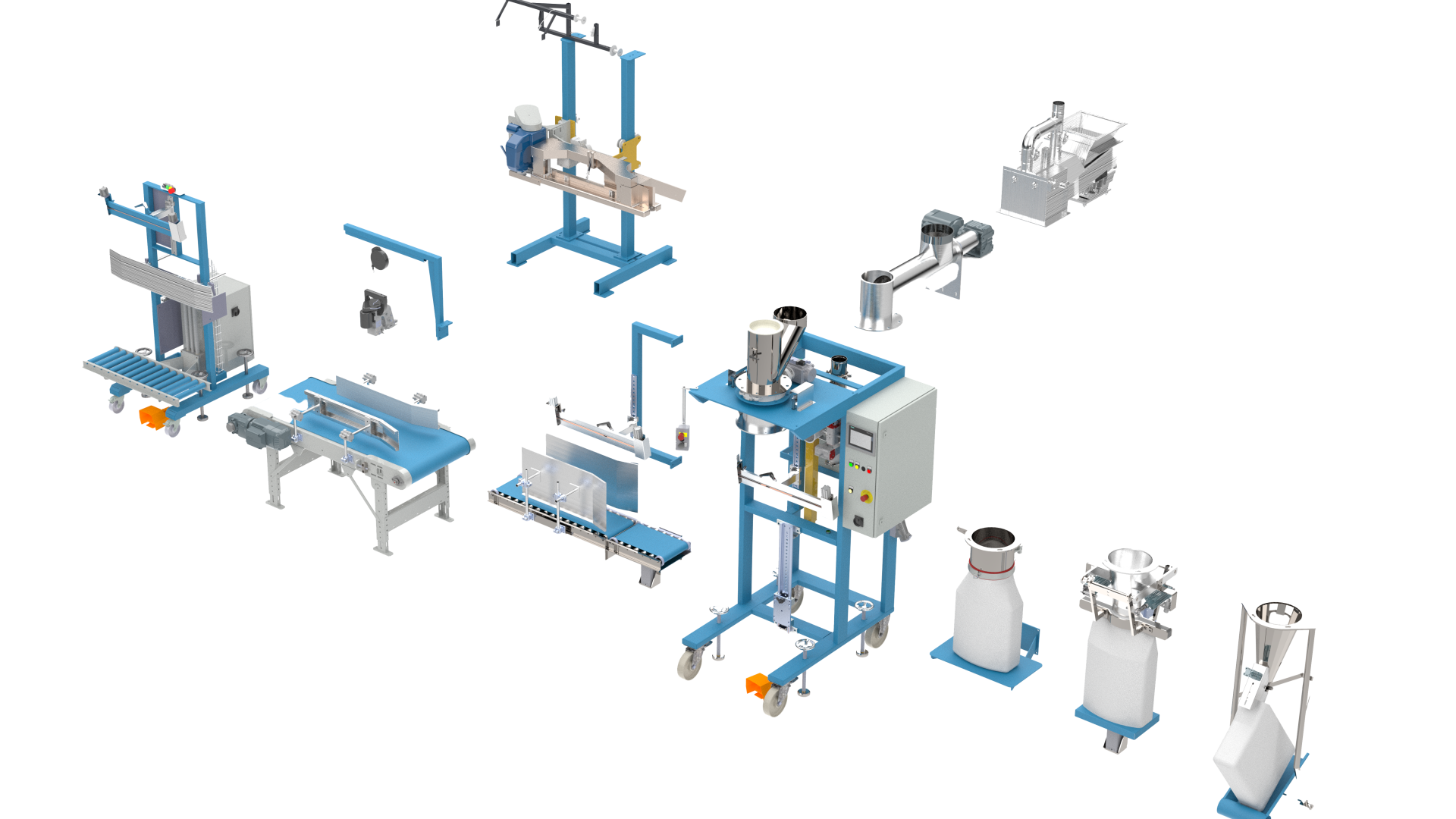

A high degree of automation can be achieved through a variety of options, such as automatic bag attachments with bag magazines, discharge controls, welding equipment or cleaning equipment. Due to the modular design, the machines can be lined up next to each other, which means that very high bagging capacities can be achieved.

Areas of application

Plastics

Fertiliser

Foodstuff

Cereals / pet food

Recycling /

solid fuels

Mineral products

Chemical products

Flours

At a glance.

Exact filling

Dosing by fluidization and elastic deformation valve, which ensure accurate and uniform filling.

Fully automatic bagging

Fully automatic bagging with tangential bag placement system and automatic valve opening on the placement arm.

Safe bag handling

Automatic 180-degree rotation and pneumatic clamping nozzle for safe handling of the bags.

Hygienic design

Easy cleaning and maximum food safety thanks to hygienic, corner-free design with integrated extraction openings.

Robust autonomy

Robust against abrasive products, easy to use thanks to intuitive display and integrated magazine for empty bags.

Technical specifications

-

Packaging material

Valve bags

-

Weighing range

10-50 kg at a resolution of 20g

-

Performance

Up to 450 bags/hour (depending on product, packaging material and operation)

-

Weighing technology

Legal-for-trade according to EU Directive 2014/32/EU

International according to OIML R61 -

Dosing systems

Dosing flap in the valve feeder

Controlled pinch valve in the valve feeder -

Electrical connection

400V 3P N+T 50Hz, Connection cable 3.5 KW

-

Compressed air connection

6 bar oil-free and clean

-

Compressed air consumption

130 NL/min without delivery air

-

Conveying air

External blower 4KW 0.8-1bar

Easy to use

The system is controlled by a compact Simatic PLC in the control cabinet. A touch panel shows all functions in plain text. The legal-for-trade weighing electronics dispense precisely, and grade parameters are stored. Customer signals and remote maintenance are optional.

Air packer with manual bag attachment

Simple machine for filling powders into valve bags.

Bag magazine with clip-on

Bag magazines in various sizes with automatic attachment system.

Easy to clean

Optimal access to the product chamber. Opening is done with quick-release fasteners.

Clean filling

Optional sealing on the filling valve. During the filling process, the valve is tightly closed.

Dust extraction at the filling nozzle

Dust that occurs around the filling station is extracted.

Ultrasonic valve closure

Optionally, the automatic machines can be equipped with a welding device.

Multi-column system

For higher outputs, several (up to 4 ) machines can be placed next to each other.

Bag clamp

Bag retaining clamp on the filling neck.