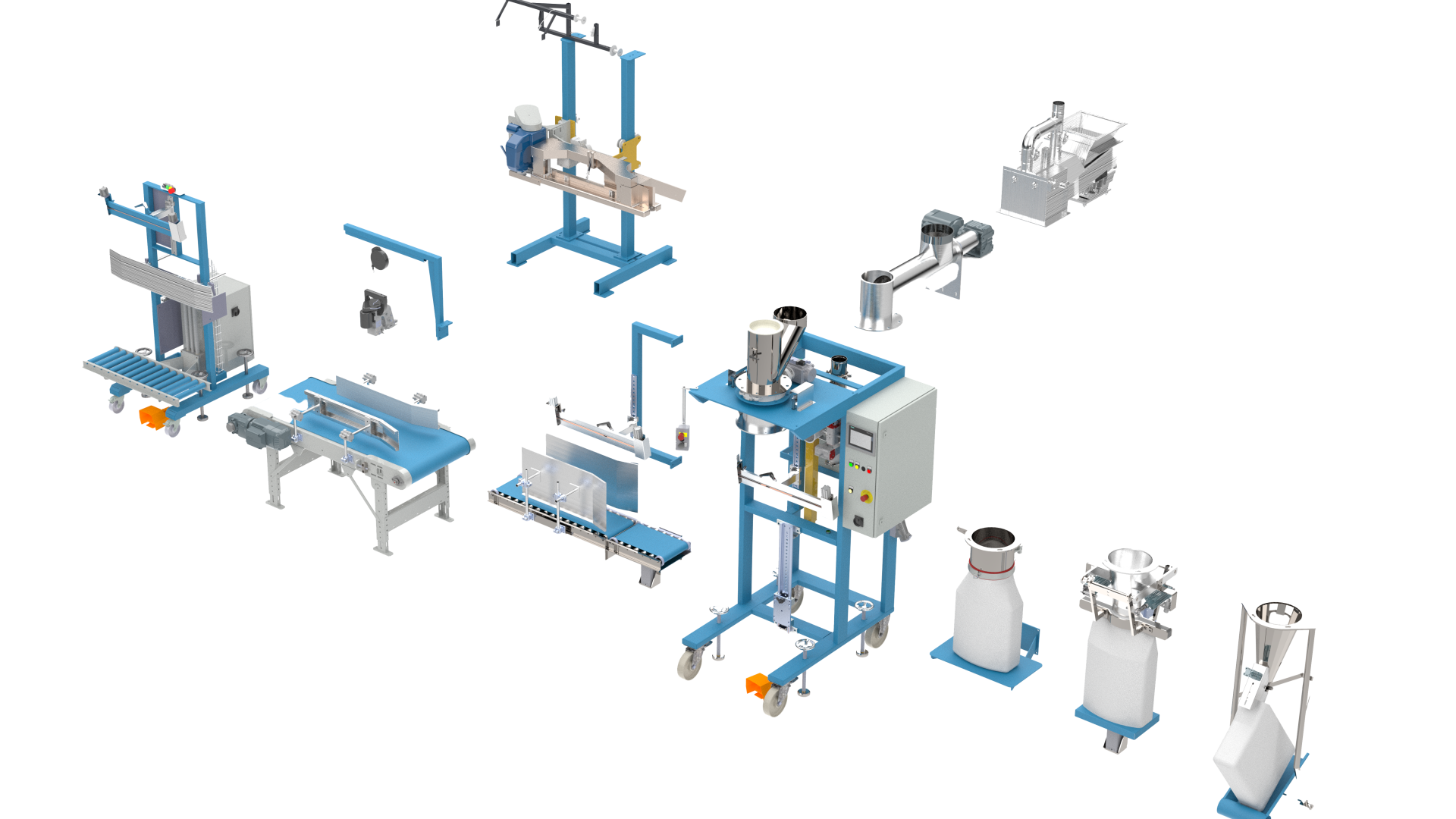

Compact bagging solution for dimensionally stable block bottom bags. The Ilersac S is a semi-automatic bagging machine specially designed for filling and sealing open, dimensionally stable bags with powdered or granular products. Its space-saving design makes it ideal for smaller production lines or as an entry-level solution for automation. The Ilersac S impresses with its simple operation, high flexibility and reliable performance – perfect for a wide range of industrial applications.

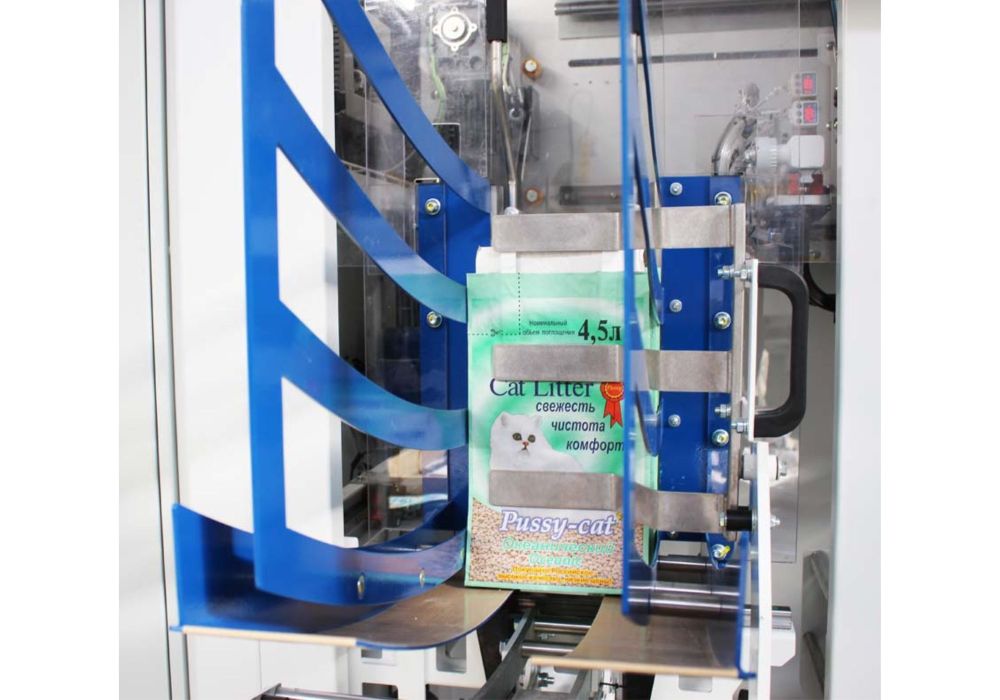

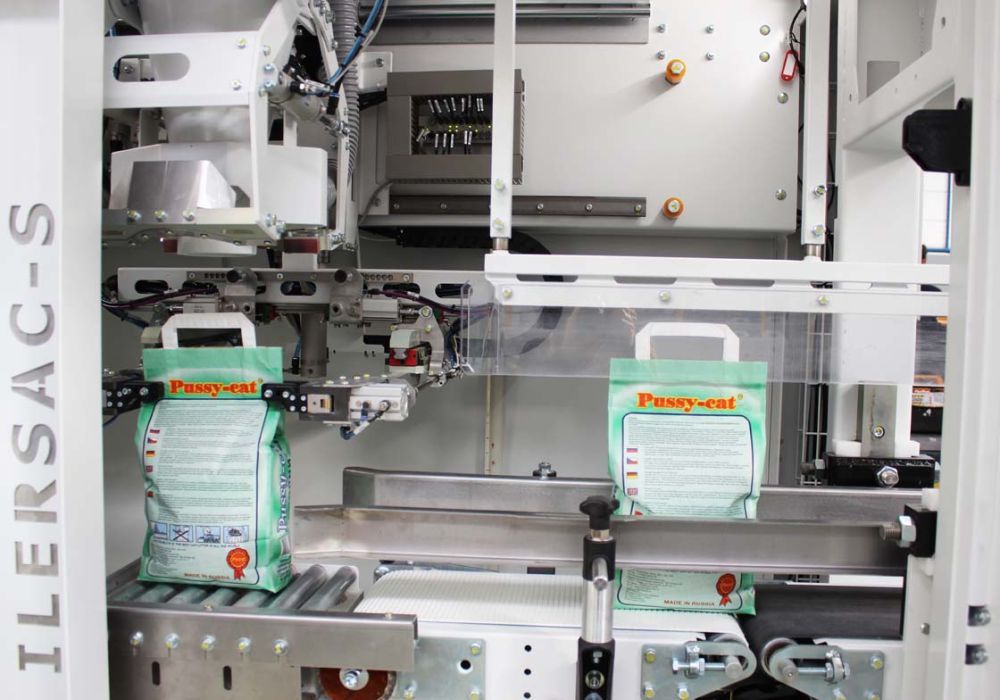

The bags are placed upright in the bag magazine, picked up automatically and attached directly to the filling spout. The filling and sealing of the bags is very reliable and efficient. The bags are then sealed (glued or sewn) and fed to the discharge conveyor. Optionally, a labelling device and a bag turner can be integrated.

Areas of application

Plastics

Fertiliser

Foodstuff

Cereals / pet food

Recycling /

solid fuels

Mineral products

Chemical products

Flours

At a glance.

High-performance

Up to 900 bags per hour

High degree of automation

Reduces manual intervention and increases efficiency.

Easy format change

Flexible and quick conversion. Versatile applications.

Bag quality

Ideal for processing SOS bags.

Performance

Highly reliable with high discharge capacity.

Maintenance

Easy maintenance, excellent accessibility.

Technical data

-

Packaging material

Open bags SOS (Self opening Sacks)

-

Product

Powder, semolina, flaky, granular granules

-

Weighing range

4–10 kg

-

Performance

Up to 900 bags/hour (depending on product, packaging material and operation)

-

Weighing technology

Verifiable in accordance with EU Directive 2014/32/EU

International in accordance with OIML R61 (small packaging regulation) -

Dosing systems

Dosing flap (free-flowing), Screw conveyor (powdery),

Conveyor belt or vibrating chute (chunky) -

Electrical connection

400V 3P N+T 50Hz, connection cable 5KW

-

Compressed air connection

6 bar Oil-free and clean

-

Compressed air consumption

250 NL/min.

Compact design

Integrated bag magazine and control system. Very compact design. Easy access to machine components. Many optional features available.

Sideways bag transport with bag gripper

Bags are transported directly from the magazine to the filling spout using the bag transport system. After filling and compacting, the bag is transported to the sealing station.

Bag filling

Customised filling spout for low-dust filling. Bag transport system with transfer system to bag sealing station.

Easy to operate

The system is controlled by a compact Simatic PLC in the control cabinet. A touch panel displays all functions in plain text. The calibratable weighing electronics ensure precise dosing, and variety parameters are stored. Customer signals and remote maintenance are optional.

Automatic sewing machine

Automatic sewing head with height-adjustable foot, thread cutter, bobbin holder, feed device, folding device and cover tape applicator. System integrated into bagging machine

Net weighers and dosing system

Above the machine on optional steel platforms. Net weighers with different dosing systems, depending on the product to be filled. Steel platforms for holding the pre-containers and weighers, easy access for cleaning or maintenance.