Ilersac L

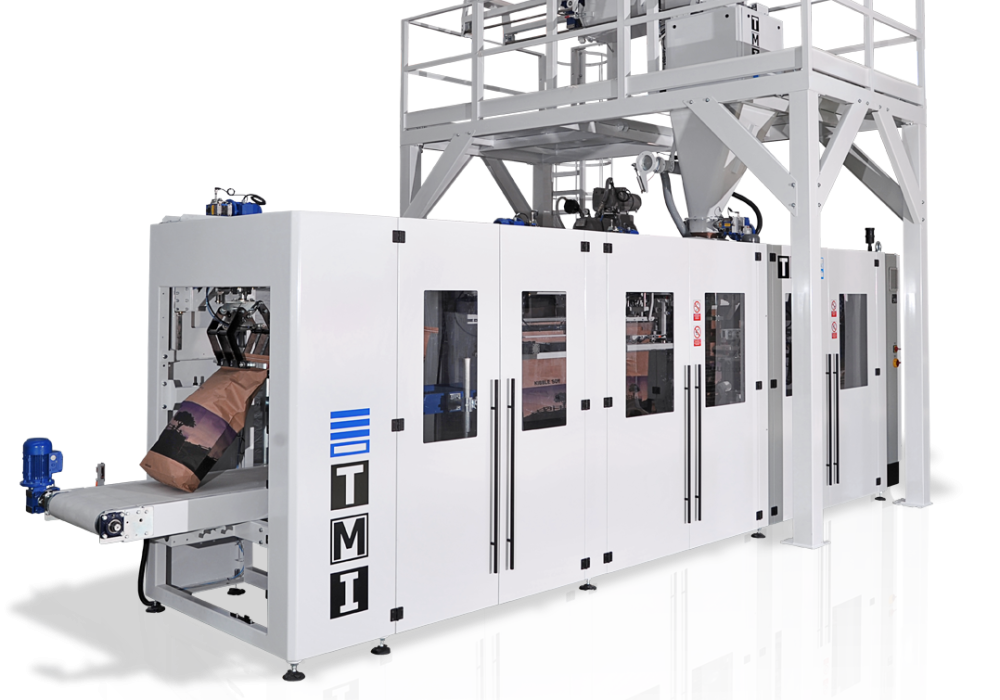

Automatic bagging machine for open bags made of PE, PP fabric or paper, with or without side gussets. The Ilersac L stands for maximum efficiency, precision and flexibility in the bagging process. As a fully automatic packaging system for open bags, it has been specially developed for powdered or granular products – perfectly suited for industries such as food, chemicals or pet food. Thanks to its modular design, the Ilersac L can be optimally adapted to your production requirements.

The bags are automatically picked up from a bag magazine and transferred directly to the bag conveyor, which delivers the bag directly to the filling nozzle. The filling process is very low-dust thanks to the tight connection. After the filling process, the bag is tightened and transferred to the subsequent sealing stations. The sealing of the bags is very reliable and efficient.

Optional additional modules such as sealing devices, venting stations or a labelling device can be integrated.

Areas of application

Plastics

Fertilizer

Foodstuff

Cereals / Animal feed

Recycling / solid fuels

Mineral products

Chemical products

Flours

At a glace.

High-performance

Up to 850 bags per hour.

Degree of automation

The modular design allows the degree of automation to be flexibly adapted to individual production processes.

Flexible and fast

Flexible and quick conversion Versatile applications.

Bag quality

Precise bag centring and low-dust filling.

Performance

Highly reliable with high discharge capacity.

Maintenance

Easy maintenance, excellent accessibility.

Technical specifications

-

Packaging material

Open bags with or without side gussets

made of paper, PE or woven PP bags -

Products

Powder, semolina, flaky, grainy, granules

-

Weighing range

10–50 kg at a resolution of 20 g

-

Performance

Up to 850 bags/hour (depending on product, packaging material and operation)

-

Weighing technology

Verifiable in accordance with EU Directive 2014/32/EU

International in accordance with OIML R61 -

Dosing system

Dosing flap (free-flowing), Screw conveyor (powdery), Conveyor belt or vibrating chute (chunky)

-

Electrical connection

400V 3P N+T 50Hz, connection cable 18 KW

-

Compressed air connection

6 bar Oil-free and clean

-

Compressed air consumption

500 NL/min.

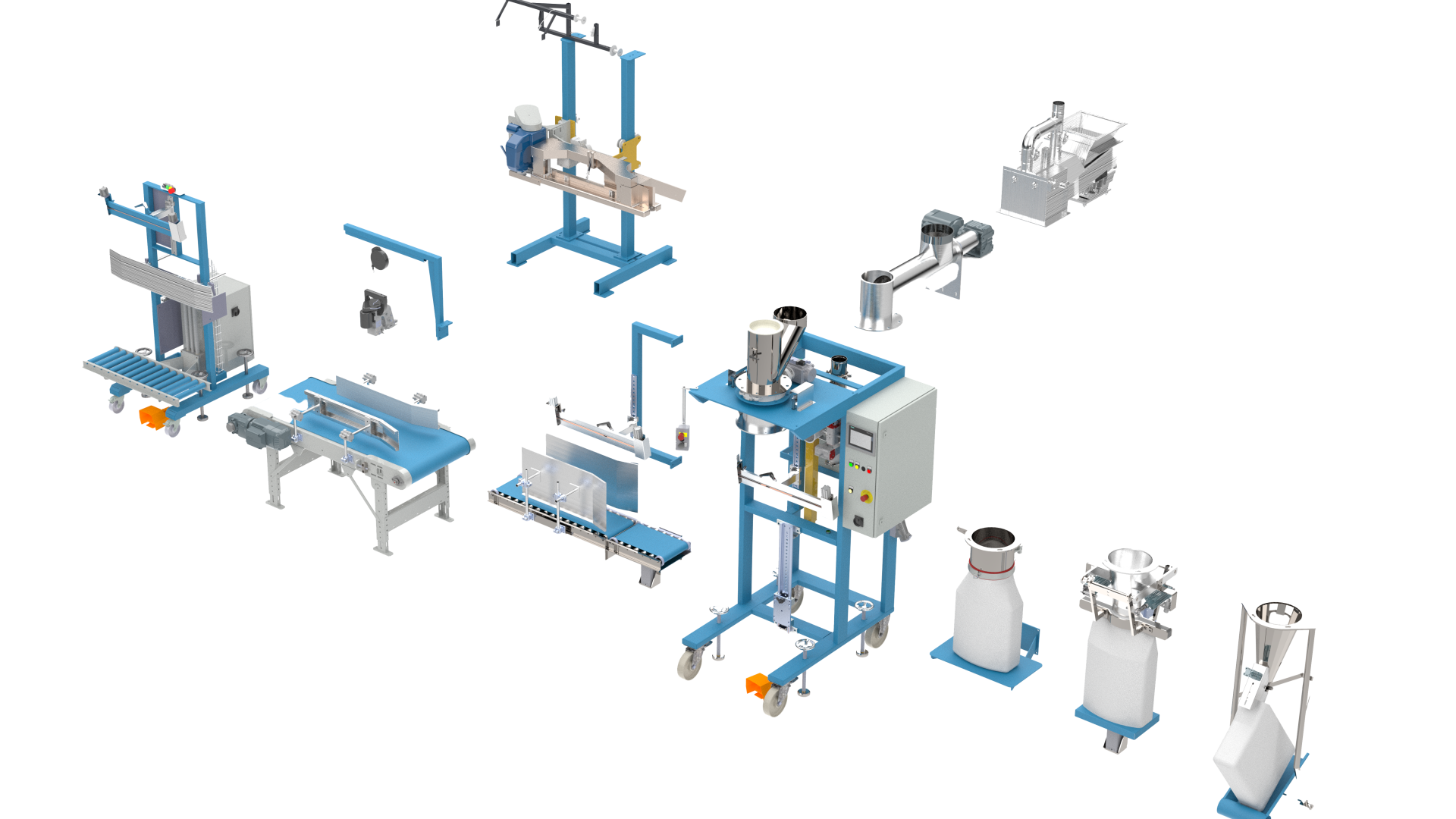

Modular design

Flexible installation, easy access to all modules and numerous optional features ensure maximum adaptability.

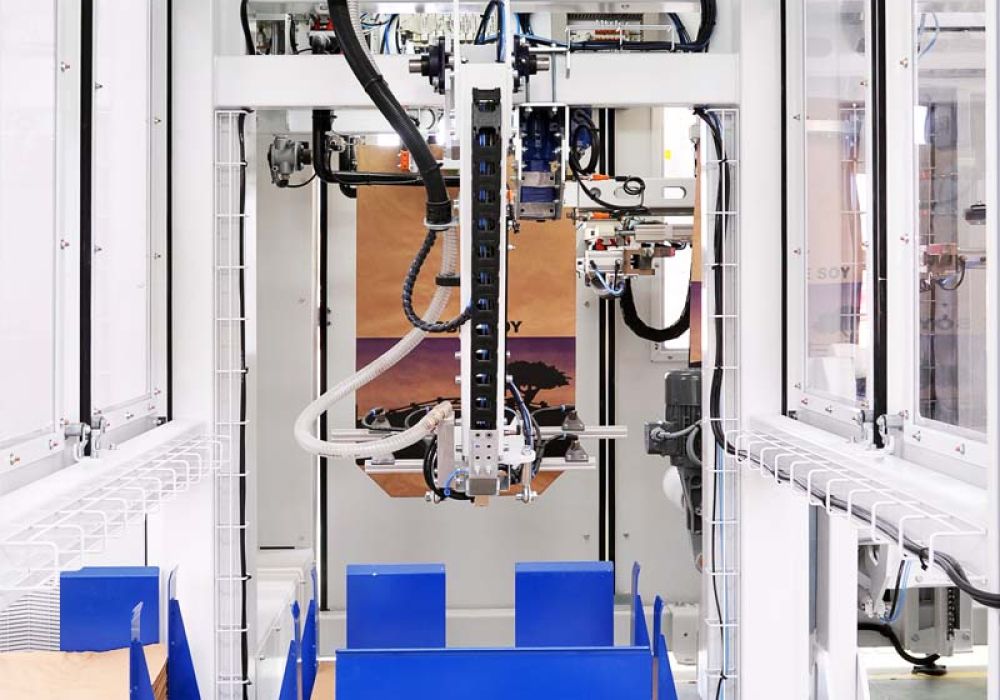

Bag magazine, bag transport with bag gripper

Bags are transferred directly from the magazine to the bag transport system using the bag pick-up device and transported sideways to the filling spout. After filling and compacting, the bag is transported to the sealing station.

Bag filling

Individually adapted filling spout for low-dust filling. Bag transport system with transfer system to bag sealing station.

Simple operation

The system is controlled by a compact Simatic PLC in the control cabinet. A touch panel displays all functions in plain text. The calibratable weighing electronics ensure precise dosing, and variety parameters are stored. Customer signals and remote maintenance are optional.

Automatic sewing machine

Automatic sewing head with height-adjustable foot, thread cutter, bobbin holder, feed device, folding device and cover tape applicator. System integrated into bagging machine.

Atex version

Atex versions available depending on explosion protection requirements. Operational safety for dusty or potentially explosive products. Dust extraction systems in Atex design.