Flexible. Precise. Efficient.

Big Bag Mobile

Flexibility is a decisive factor in modern silo systems – especially if several filling silos are to be served with a single filling system. Our mobile big bag filling line was designed precisely for this area of application: it combines the mobility of a mobile platform with the high degree of automation of a stationary big bag filling system.The entire system is built on an electrically mobile platform that can be easily and precisely positioned under various silos using joystick control. Thanks to battery operation, the system is independent of a fixed power supply and recharges itself automatically during filling operation. The platform is extremely manoeuvrable and can rotate on its own axis in the smallest of spaces – including comprehensive safety equipment thanks to all-round protective strips and light grids.

The centrepiece of the mobile line is the high-performance big bag filling station. It enables the fully automatic filling of big bags or large cartons – optionally also in a double pack on a pallet. The intelligent combination of hydraulically lifting roller conveyor and fixed filling head ensures consistent working positions, regardless of the big bag size. An integrated vibrating table ensures optimum compaction of the bulk material during filling.

The pallet logistics are also well thought out: an automatic empty pallet magazine with separation and driven roller conveyors ensure a continuous supply of material – from empty to closed big bags. The final closing station allows either manual or automated closing and labelling of the bags. The ergonomic design and ease of operation enable virtually uninterrupted operation with minimal labour requirements.

With this mobile big bag filling line, we offer an innovative solution for all companies that value flexibility, process reliability and maximum efficiency when filling bulk goods.

Areas of application

Plastics

Fertiliser

Foodstuffs

Cereals / pet food

Recycling /

solid fuels

Mineral products

Chemical products

Flours

At a glance.

Mobile version

For flexible use within a silo building

High discharge rate

Automatic filling line with a high degree of automation

Ergonomic filling

Automatic filling with little manual intervention

Robust construction

Sturdy and maintenance-free construction for many years of use under demanding operating conditions

Highest precision

Ball-bearing load cells for accurate weighing

High level of automation

Variety memory for all functions

Flexible design variants

System can be adapted to the structural conditions

Technical data

-

Packaging material

Big bag made of fabric or aluminium composite material with or without inliner

Octabin or large cardboard boxes -

Weighing range

250-1,500 kg with resolution 0.5 kg

-

Performance

30-50 bags/container per hour

Depending on the product, the packaging materials and the skill of the operator -

Weighing technology

Verifiable in accordance with EU Directive 2014/32/EU

-

Material

Painted mild steel

Inlet and parts in contact with the product in stainless steel, DIN1.4301, blasted

Painting Primer with top coat in RAL 7010 -

Electrical connection

400V 3P+N+PE 50Hz, connection cable 11KW

Special voltage possible -

Compressed air connection

6 bar Oil-free and clean

-

Compressed air consumption

5Nm³/hour

Easy to operate

The system is controlled by a compact Simatic PLC in the control cabinet. A touch panel displays all functions in plain text. The calibratable weighing electronics ensure precise dosing, and variety parameters are stored. Customer signals and remote maintenance are optional.

Manual bag clamp

The manual hand bag clamp is a practical tool for quickly and securely closing bags. Robust, handy and easy to use.

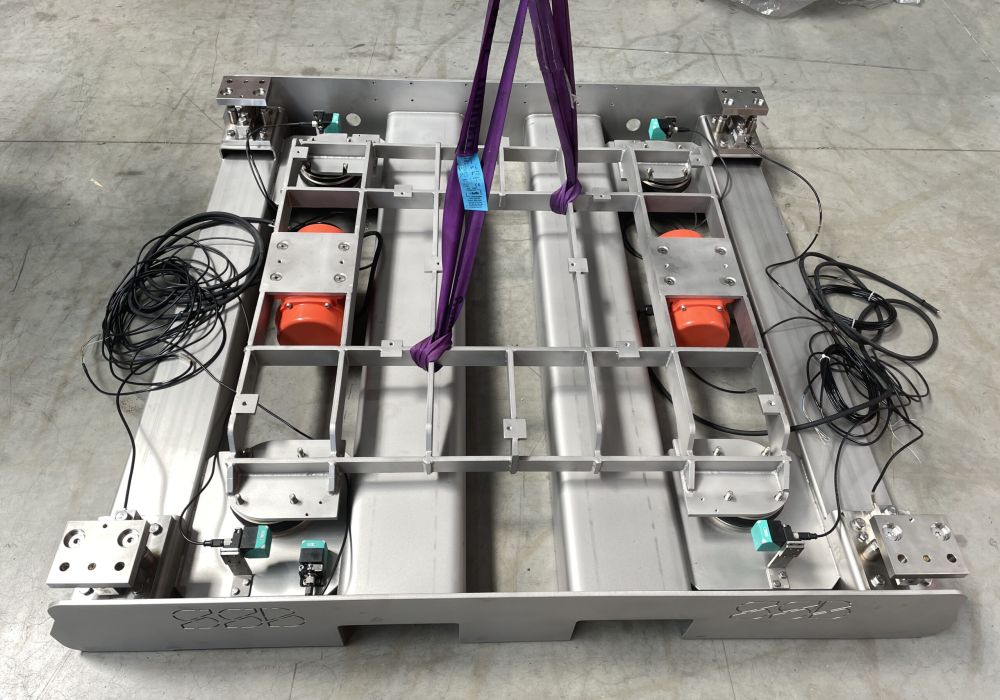

Weighing frame with ball support

Weighing frames with ball supports ensure precise weight measurement while offering a high degree of freedom of movement. Ideal for dynamic applications where accurate measurements and flexibility are required.

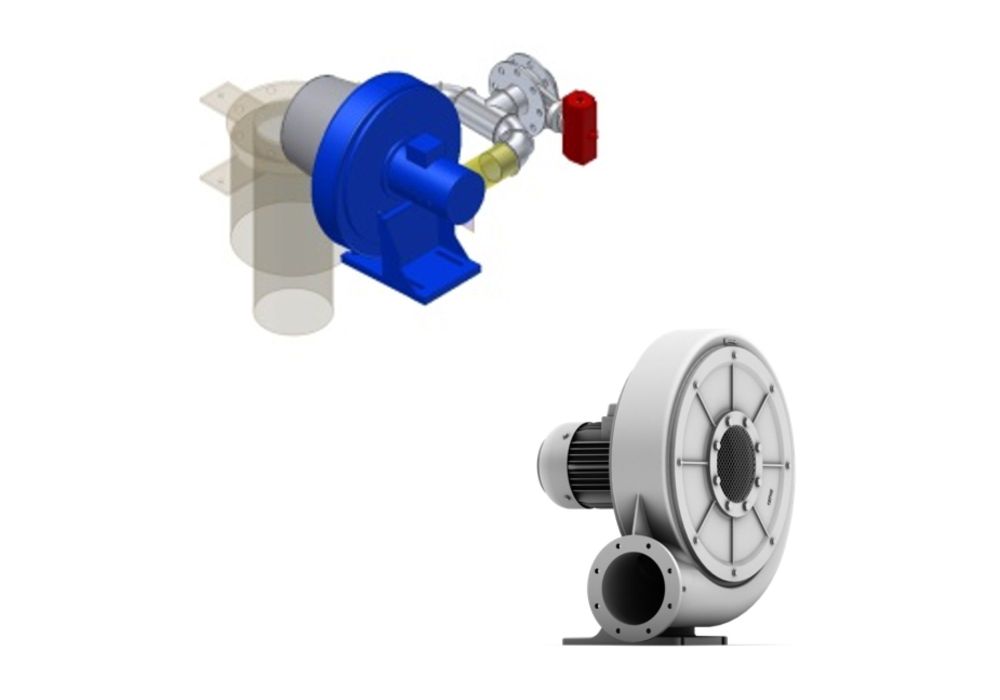

Inflation device

Big bags with liners must be inflated before filling so that the liner can spread out in the bag. Radial fan. Control in the panel. Adjustable inflation time. Bypass valve Fan filter. Piping up to the filling nozzle.

Vibrating device

Our freely suspended vibration frame, decoupled from the weighing frame, ensures gentle movements thanks to air cushions. Freely programmable vibration cycles guarantee an optimum fill level in every bag – efficiently, gently and reliably.

Atex version

Atex versions available depending on explosion protection requirements. Operational safety for dusty or potentially explosive products. Dust extraction systems in Atex design.

Automatic load hooks

The rear load hooks automatically move forwards to make it easier for the operator to hook in the big bags. After filling or an optional jogging cycle, the hooks open automatically. The position of the hooks can also be flexibly adapted to different bag cross-sections.

Height adjustment

For different container heights and user-friendly operation. The hydraulically operated lifting device brings the bag into an optimum position when attaching and filling. This device is indispensable for different bag formats.

Dust removal system

Customised filter systems with quick-change filter cartridges, automatic filter cleaning. Piping and bypass valves. Flow monitor with pressure difference control. Optional explosion-proof design.