Palletizing robot Ai700

The Okura Ai700CE palletizing robot reliably and efficiently palletizes bagged goods, cartons, and canisters, packing them securely and compactly for further transport. The new robot from Okura is available in three different versions, which differ in terms of bagging capacity. This allows each customer to select the robot that best suits their requirements. The robots are characterized above all by their high reliability and functionality. They are virtually maintenance-free and receive rapid assistance from support centers worldwide.

The 4-axis model enables precise and fast operation and can be used in a wide range of applications and thus for a variety of products. The robot can be programmed using integrated software, making it adaptable, fast, and flexible. The robot also offers the fastest cycle time in its class.

Areas of application

Plastics

Fertilizer

Foodstuffs

Grain / Animal feed

Recycling /

solid fuels

Mineral products

Chemical products

Flours

At a glance.

User-friendly

Intuitive operation and easy-to-understand controls, allowing users to work productively without lengthy training.

Wide range of applications

Versatile use in different scenarios and industries.

High reliability

Stable performance and consistent results even during intensive use, minimising downtime.

Low maintenance

The robot requires minimal servicing, components are durable and easily accessible, reducing interruptions to operation.

Technical specifications

-

Palletising capacity

max. 610 bags per hour

-

Working area

4 axes

R axis: 360°, D axis: 2,300 mm

O axis: 1,518 mm, T axis: 440° -

Loading capacity

140 kg including gripping tool

-

Net weight

1,335 kg (without gripping tool)

-

Pneumatic air consumption

180 l/min – with optimal pallet handling 300 l/min

-

Ambient temperature

0-40°C

-

Electrical connection

3-phase 380/400/415/480V AC +/- 10% 50Hz, 6.5KW

Simple control

The Okura Ai700 is controlled via the control panel. After switching on, it performs a reference run, after which programmes can be loaded or edited. Movements such as position, orientation and speed are set step by step. The system constantly monitors sensors and safety areas and stops automatically when it encounters obstacles.

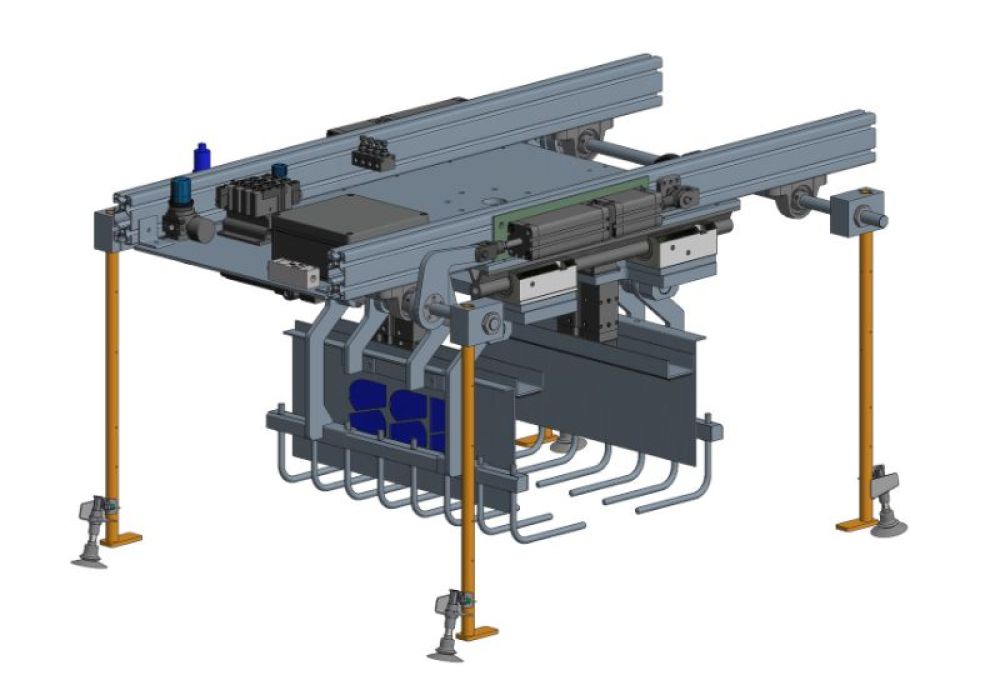

Bag grippers

A wide range of powerful gripper arms is available, enabling safe and efficient handling of a wide variety of products. The bag grippers cover a wide range of applications and ensure stable, gentle and reliably controlled material flow.

Bag gripper for empty pallets + protective sheets

The optional add-on module for the robot hand expands the Okura Ai700 with pallet handling and protective sheet placement. The gripper positions the pallets precisely so that bags can be palletised efficiently, stably and gently.