Ilersac W

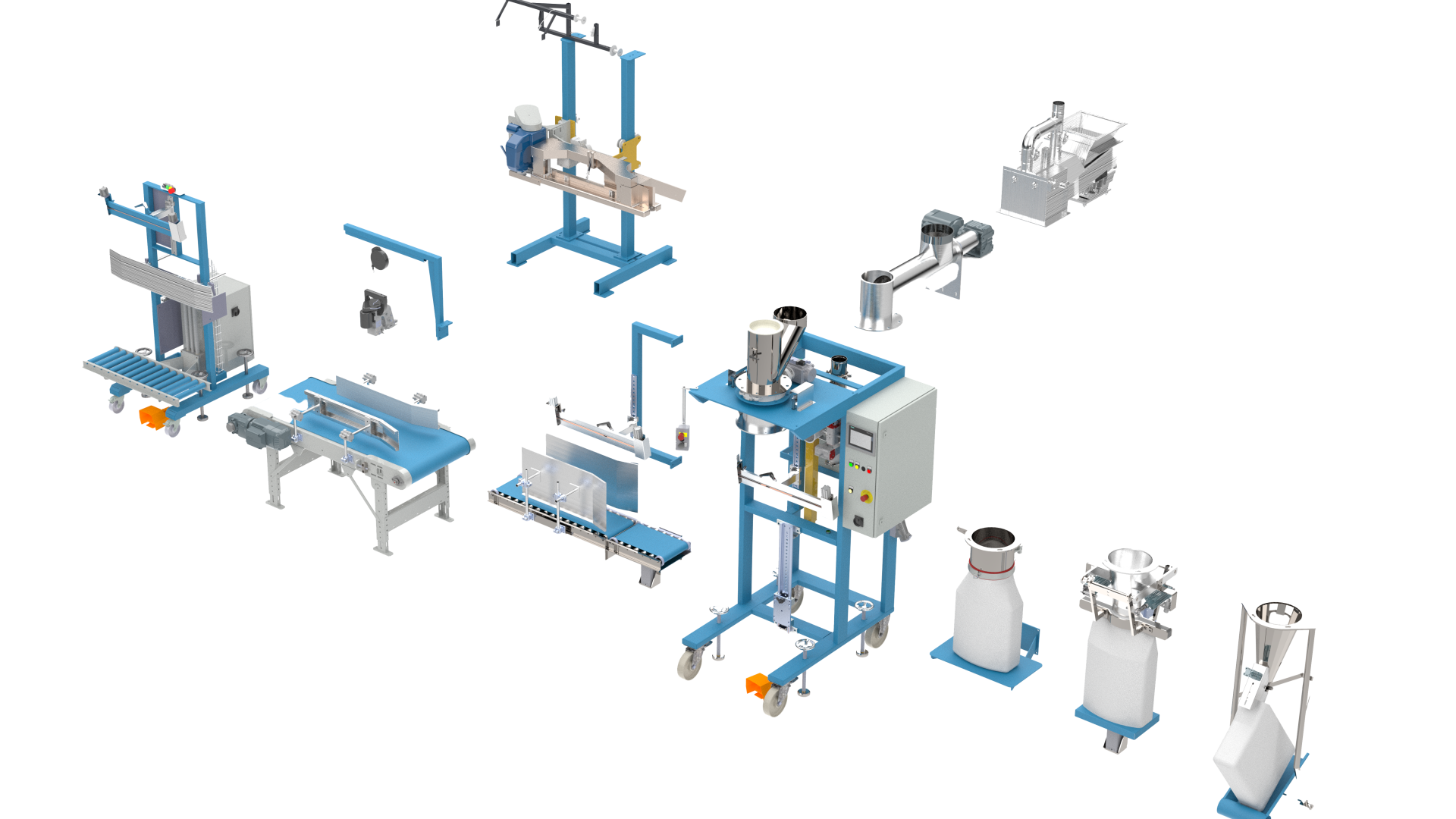

Automatic bagging machine for open woven PP bags with or without side gussets. The Ilersac W stands for maximum efficiency, precision and flexibility in the bagging process. As a fully automatic packaging system for open bags, it has been specially developed for powdered or granular products – perfectly suited for industries such as food, chemicals or pet food. Thanks to its modular design, the Ilersac W can be optimally adapted to your production requirements.

The bags are automatically picked up from a sack magazine, centred and labelled. The bag is then picked up and placed on the filling spout. The filling and sealing of the bags is very reliable and efficient.

The bags are then sealed (sewn) and fed to the discharge conveyor. Optionally, an additional labelling device and a bag turner can be integrated.

Areas of application

Plastics

Fertiliser

Foodstuff

Cereals / pet food

Recycling /

solid fuels

Mineral Products

Chemical Products

Flours

At a glance.

High-performance

Up to 1,400 bags per hour

Degree of automation

Reduces manual intervention and increases efficiency.

Format change

Flexible and quick conversion

Versatile applications.

Bag quality

Precise bag centring and perfect filling.

Performance

Highly reliable with high discharge capacity.

Maintenance

Easy maintenance, excellent accessibility.

Technical Data

-

Packaging material

Open polypropylene bags with or without side gussets

-

Products

Powder, semolina, flaky, granular, granules

-

Weighing range

10–50 kg, at a resolution of 20 g

-

Performance

Up to 1,400 bags/hour (depending on product, packaging material and operation)

-

Weighing technology

Verifiable in accordance with EU Directive 2014/32/EU

International in accordance with OIML R61 -

Dosing systems

Dosing flap (free-flowing), Screw conveyor (powdery), Conveyor belt or vibrating chute (chunky)

-

Electrical connection

400V 3P N+T 50Hz, connection cable 4.5KW

-

Compressed air connection

6 bar Oil-free and clean

-

Compressed air consumption

650 NL/min.