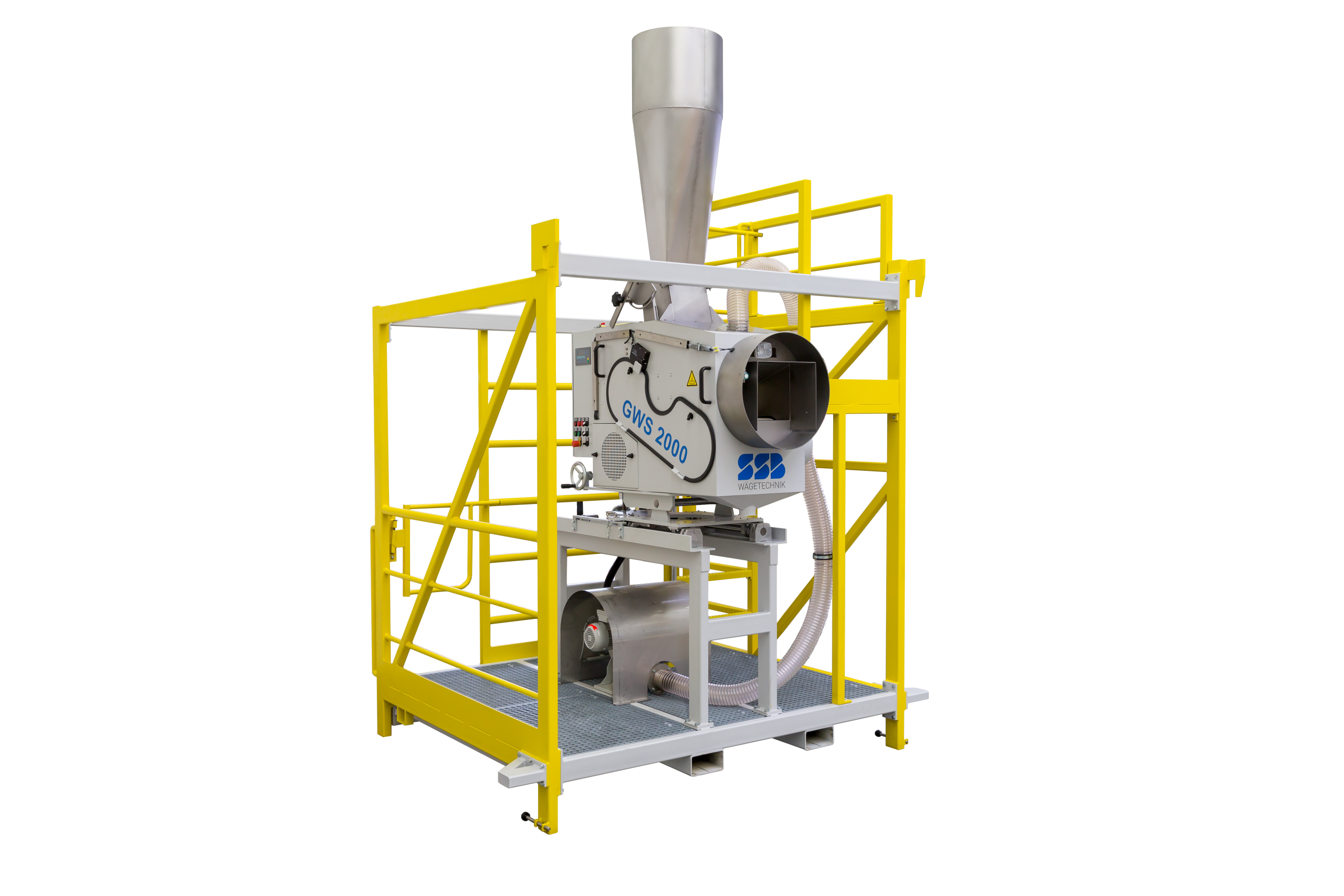

GWS 2000 Granulatwerfer

Efficient filling of 20-40 ft containers with bulk goods

The GWS 2000 is a powerful filling solution for the rear loading of 20-40 ft containers with loose, free-flowing bulk materials. Ideally suited for granulate, grain and pellet-shaped materials with a grain size of 1.5 to 10 mm, e.g. plastics, grain, sugar, coffee or animal feed.

Atex version available.

Functionality

The granulate thrower is mounted on a sturdy supporting structure which, depending on the model, is either driven directly up to the container or attached to it. Two integrated platforms provide the operating personnel with safe access and an excellent overview.

The filling opening of the container inliner is simply connected to the ejection chute of the machine. Once the system has started, the silo discharge gate is opened – the material is now accelerated via the centrifugal conveyor and precisely thrown into the container.

Operation & safety

It is controlled via a modern control panel with which the height and throw range can be conveniently adjusted.

Thanks to the integrated overfill protection, the product flow is automatically stopped before overfilling occurs. Fine-tuning or re-dosing of the residual quantity is done manually – simple and controlled.

Areas of application

Plastics

Fertiliser

Foodstuffs

Cereals

Recycling /

solid fuels

Chemical products

Pet food

Mineral products

At a glance.

Flexible & efficient

for various products such as animal feed, grain, plastics

High performance

up to 90 tonnes per hour

Highest precision

Short loading times

Hygienic & easy to clean

Ideal for sensitive products

Technical data

-

Packaging material

20′-40′ container with inliners

-

Pure filling capacity

approx. 30-90 tonnes/hour

-

Medium filling weight

approx. 15-18 tonnes/hour (20′ container) with a bulk density of 0.5kg/dm³

-

Filling level

approx. 95% of the theoretical filling level

approx. 90% of the total volume

(20′ container) -

Throwing distance

approx. 5-12 m (depending on product)

-

Belt speed

approx. 19 m/s (+/-30%)

-

Dead weight

approx. 670 kg

-

Weight with frame

approx. 1,975 kg with all specified options

-

Recommended stacker

3 t (only with trailer frame)

-

Transport route height

approx.. 4 metres

Design example

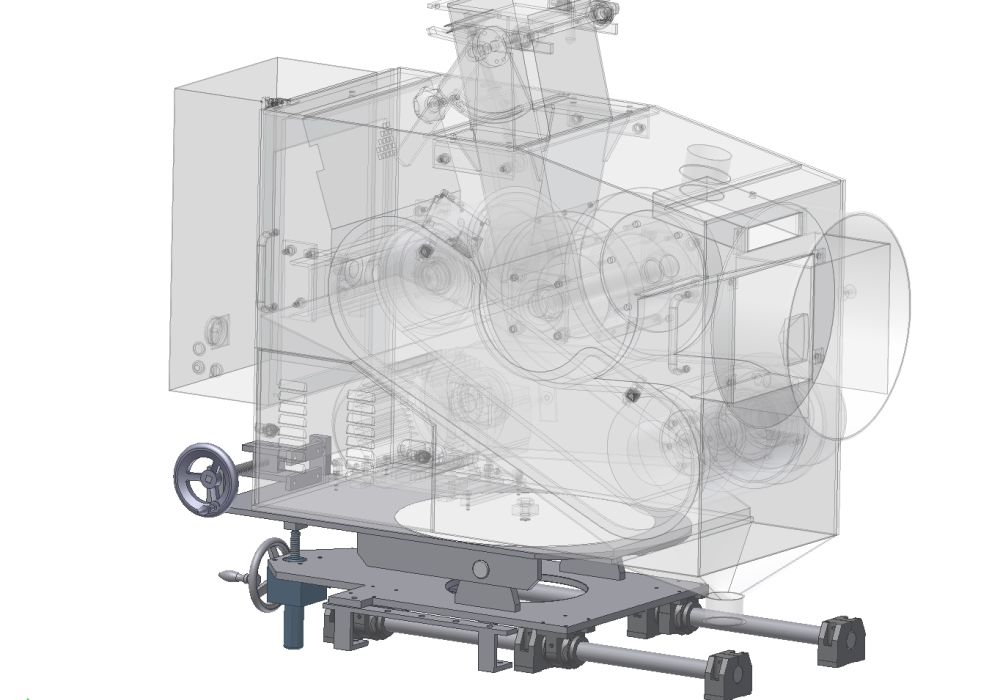

Product ejection hopper

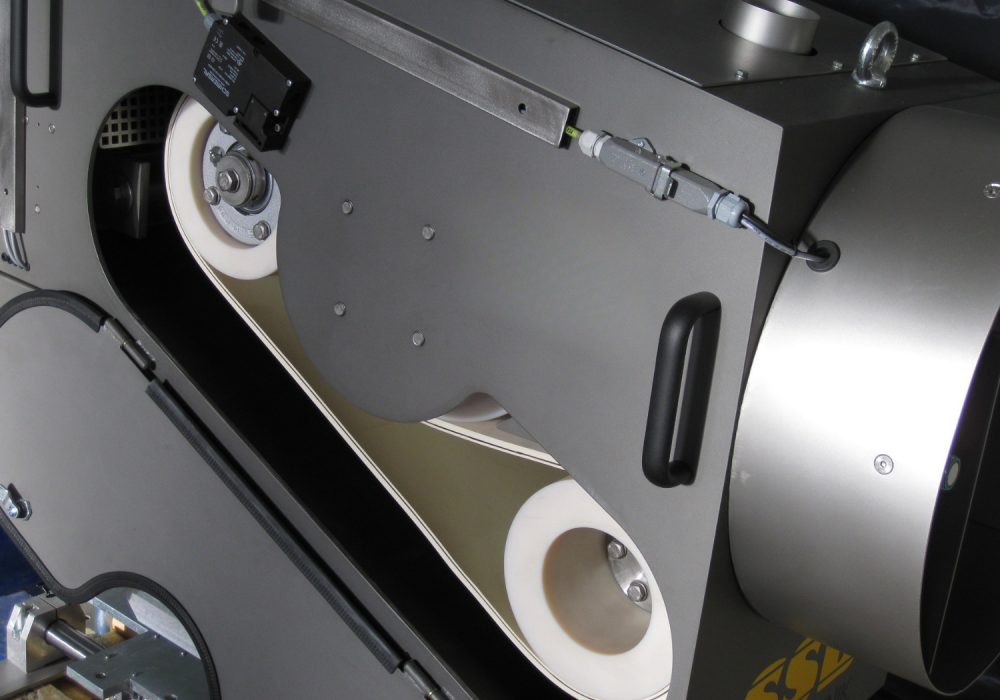

A specially adapted transition piece ensures an exact connection between the drum and the conveyor belt. This reliably prevents the material from escaping sideways. The discharge spout is located on the product guide channel – round in shape with a diameter of 480 mm and a length of 200 mm. The inliner can be easily and securely attached to this spigot using a clamp.

Belt change

The conveyor belt is a special design, suitable for high circulation speeds. No machine part needs to be dismantled to change the belt. If the belt needs to be replaced, the belt tension simply needs to be released. The belt can then be changed very easily.

Drum construction

The length of the conveyor belt and the radius of the drum are essential for optimum acceleration of the material. A 360 mm diameter drum with a 250 mm wide and 70 mm deep product channel is used. To give the conveyor belt stability and the best possible support, the side bars are 60 mm wide.